Our goal throughout this project was to restore the home to its original beauty. We have paid particular attention to preserve as much of the original home as possible while mitigating the effects of years of deferred maintenance. We knew the home needed a roof, plaster repair and a new heating system. The home held many surprises most of which were expensive, unplanned repairs. We are about halfway through the project and the house is really coming together well. When original home elements needed to be replaced for safety or performance reasons, we preserved them in the “history cellar.” This includes wall sconces, lights and some of the original roof tiles. The home is undergoing a full rehabilitation to restore it to its original state. Some rooms like the kitchen and many of the bathrooms are being updated to modern standards. The kitchen and most of the bathrooms had been renovated in the 50s, 60s and 70s and represented neither the original design or usable configurations in 2020. While the orange shag carpet on the main level is in surprisingly good shape, we chose to retire its use and expose the amazing wood floors. Below are details of the extensive renovations that have been completed or are currently underway. All phases have been permitted and inspected by the City of Duluth.

Roof:

The original roof was still on the house when purchased in 2019. It was a green tile roof and had long passed its service life after 110 years. The roof had many leaks and each attempt to patch the roof only served to crack additional tiles. The leaks had damaged the ceiling in six of the seven bedrooms and in three of the bathrooms. We looked at replacing the roof with tile but the cost was estimated at $250,000 plus any repairs to the roof deck that might be discovered when the tile was removed. We selected a 30 year architectural shingle that closely matched the tile color. The new shingles are designed for high wind areas and should stand well against winds coming off Lake Superior.

The roof was replaced by TRS Builders out of the Twin Cities. They worked over two weeks, filling two 40’ dumpsters with tile, batons and bad decking. When the tile was removed the 1×8 roof decking had over a dozen rot holes that had been let water into the attic.

All water damaged decking was replaced, approximately 1/3 of the original deck. They then installed a second ¾” tongue and groove plywood deck on top of the 1x8s. They re-flashed all the roof vents and fireplaces. This gave us a new water tight envelope just in time for winter. We got the first snow just days after completion.

Utility systems:

The basement ceiling was a maze of 110 years of wiring, heating pipes, water pipes, waste pipes, and other misc. pipes and wires. Because of the freeze damage, 100% of the boiler pipe system was removed and replaced. The electric system also required a complete removal and replacement to bring it up to code. The plumbing systems were also upgraded and all new supply lines to every sink, toilet and tub were replaced. Some stack waste pipes were retained but almost all the old mechanical, plumbing and electric services were modernized.

The trunk elevator presented an opportunity to run the needed gas, electric, heating and cooling systems to all four floors of the house. While the elevator is a cool feature of the house, it was designed for moving trunks and furniture and could only be operated by having someone in the attic spinning the wheel. We did not want to rip out all the woodwork and detailed moldings on the main floor, so instead decided to retire the elevator on the basement level and use the shaft to support the utility systems. With some modifications to the car, the elevator could be put back into use.

Heat:

The home had suffered freezes through multiple winters. Records show that gas to the boiler was shut off in 2008 and heat was not restored until February of 2019. Electric heat was used in some of the basement spaces. The majority of the house was subject to the North Shore Winter. About half of the radiators had frozen and burst and had to be removed. To preserve the original look of the home, we moved undamaged radiators from the second and third floor to the main level and the basement. The basement and main floor (1st floor) now have fully functional boiler heat and a preserved look consistent with its appearance in 1909.

To accomplish this, Brent’s Heating and Cooling, installed two new high efficiency on demand boiler units. They work in series to economically produce the hot water needed to heat even in the peak of winter. Since many of the radiators were freeze broken, there were going to be many broken pipes, we decided not to use any of the old heating pipes. Rather they were replaced with PEX. This removed the risk of any of the 110 year old pipes failing and causing water damage and loss of heat.

To heat and cool the 2nd and 3rd floors (six bedrooms and four bathrooms), two high efficiency gas furnaces were placed into the attic. In addition to creating two more zones, it meets the needs of modern living while not greatly changing the esthetics of those rooms. The home now has four heating zones and RF sensors in key rooms to balance the heat, along with central air conditioning.

Asbestos Abatement:

As we retired the old boiler and all of the old pipes, we decided to have the pipes with asbestos insulation professionally remediated. All pipes in open areas (the garage, furnace room, basement bathroom, future home theatre, water and electrical rooms). Over 1700 feet of pipe were removed using the wrap, cover and cut technique. This minimized aerosolization and allowed the work to be done in about two weeks. Air quality was checked both before and after abatement and met required levels. Waste trail documentation (proof it was sent to a hazardous waste dump) is located in the “history cellar.” There are no exposed pipes left in the house with asbestos insulation.

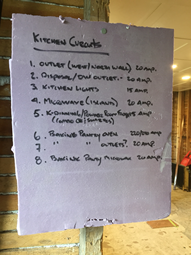

Electrical Upgrade:

The home had a newer power meter and a 200-amp breaker box in the basement. We were encouraged that some circuits had been modernized and brought up to code. We soon realized that other than the main breaker box, the system was mostly run through a second-floor fuse panel. That would need to be upgraded and brought up to code. Jim Strohmier, from Bridge Electric, was selected to help us update the electric system in the house. Jim is a master electrician and has extensive experience working on older homes in Duluth. While working as an electrician for UMD, he worked on the historic Glen Sheen Mansion on Lake Superior.

Jim developed a plan to retire the fuse panel and place modernized breaker panels in the house. To date, he has brought the electrical systems up to code in the kitchen, baking pantry, all six bedrooms and five bathrooms, the new laundry room, garage, and basement spaces. The original fuse box is now disconnected from the power. It remains in place in the second-floor hallway and still has the original paper and string labels attached to the old fuses.

Plumbing:

Freeze damage was not limited to the heating pipes and radiators. Most of the supply lines and some of the traps on the drain pipes froze and burst from the lack of heat in the house. The decision was made to replace all the supply lines with PEX and replumb most of the plumbing system. The conversion of the second floor sewing room into a bedroom level laundry room made great sense for modern living. The home still had the triple sinks in the basement that were the site of the original laundry room. It was located over the house’s cistern. All the rain gutters on the house originally drained into the cistern where the water could be drawn for laundry and other uses. The maze of old water supply lines in the basement have been removed and brand new PEX tubing supplies every faucet in the house. Additional outdoor, frost free exterior faucets were added as well.

History Cellar:

One of our goals was to restore and preserve the history of the home. The home has three cellars and we have converted one into a depository of artifacts from the house. As previously noted, the home had a tile roof until 2019. We kept and placed into the History Cellar (HC) examples of each of the tile styles that came off the roof. This gives a reference point for what was originally on the roof. There are also samples of the new singles. The home had many wall sconces instead of ceiling lights. Some of the bedrooms had two to four of these lights. Only a few of these lights were still in place (in the master bedroom) so they were removed during renovation and placed in the HC. These lights held two small candle style bulbs and produced very low lumens so they were preserved and modern LED lighting will be used to illuminate the rooms. There are also a number of chandeliers from different rooms that are in the HC.

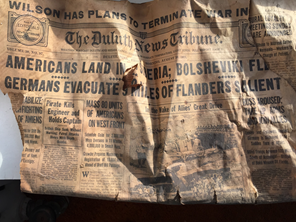

One interesting set of items in the HC are things found in the walls. In addition to liquor bottles, beer cans and children’s blocks, there were a number of newspapers dating from 1918. All of those are in a tote in the room to protect them from any moisture. And then there was the gun under the radiator, it was a cap gun…from the 1950s.

Mystery in the basement:

The walls and radiators were not the only mysteries we found. The ceiling in the basement recreation room was another mystery. When we first purchased the basement Drying Room (how the room is named on the blue prints) was converted into a rec room some time in the mid century. It had Pine walls and ceiling and 4×4 beams that appeared to be under great weight. We were concerned that the floor may have partially cracked or collapsed and that this odd false ceiling was hiding a structural issue. The horizontal supports had bowed under the weight of what ever sat on top. The false ceiling and 4×4 support structure ran the length of the 20×50’ room. We wanted to see what if any issues existed in the living room floor above. The picture below shows the ceiling structure and cement blocks that lined the entire ceiling of the room. The laundry room also had a false ceiling that was lined with two to three layers of cement blocks.

There was a section that was open from a plumbing repair and we could see into the false ceiling. There was about12” of open space and none of the floor above was failing in any way. The main level floors are 16” thick and made up of floor blocks. We were relieved to not have any floor failures but still had no explanation for the false ceiling covered in cement bricks.

There have been a number of theories to why this was added. The most likely was that they were installed to add further sound insulation. Other thoughts were this was some kind of reinforcement for a bomb shelter. The most interesting theory was that it was added for sound proofing to cover for a speakeasy in the basement. There is no data or other clues to help us to reach a conclusion. Feel free to email us with your thoughts of why you would add a false ceiling in this part of the basement.